-

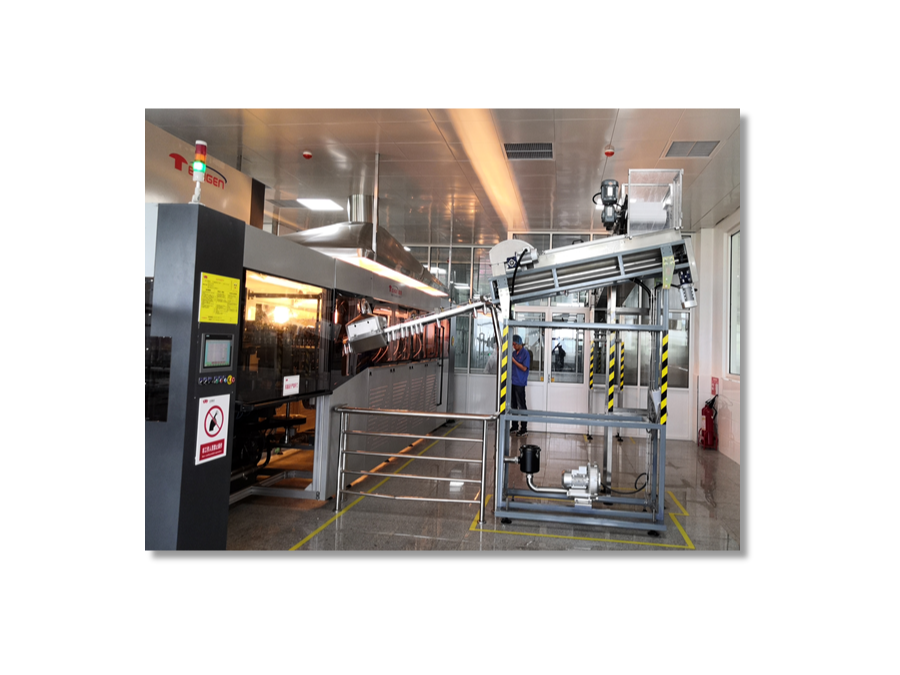

Multiple specifications meet

Filling speed can be according to the actual needs of customers to meet multiple specifications and requirements. Such as:350ml~500mlAvailable in the speed range8000BPH~36000BPHTo choose from,4L~6LProducts can do that6000BPH.Compatibility can also be considered.

-

Filling system

Filling health grade and filling products: super clean filling method, can fill most yogurt, fruit juice, protein drinks, tea drinks and other products. And can be optional to add fruit filling system and suitable for fruit filling system.

-

One key operation

The sealing method usually adopts screw cap, which can be used for magnetic torque cap which requires mechanical adjustment of torque, or servo electronic torque adjustable cap which can be adjusted on the touch screen by pressing keys.

-

A variety of materials

Suitable for various container materials such asPET,HDPE.PPAnd so on.

-

The sterilization ways

Sterilization, container sterilization using dry vaporization hydrogen peroxide sterilization heating air decomposition, cover sterilization usually using ultraviolet sterilization, if the customer needs a higher level, can also use hydrogen peroxide dry sterilization way to deal with the lid.

-

Accuracy of unity

Liquid filling method adopts weighing filling, empty bottle weighing, gross weight clearing, net weight filling, weight check after filling and so on. Do not fill without bottles, empty bottles do not fill unqualified weight, filling weight incorrect automatic elimination and other practical functions. At the same time, it has the advantages of high filling precision, low filling discrete value and high precision uniformity.

-

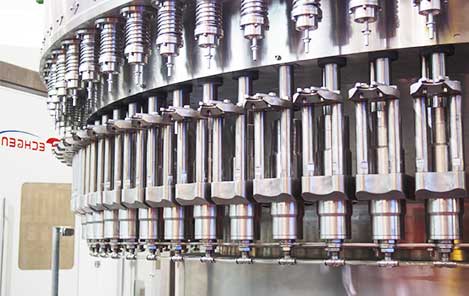

Piston filling valve

For products containing particles, we can directly choose our special piston filling valve for mixed particles, which can cut off fruit and part of fiber particles. Our specially designed piston filling valve has high precision.

-

Two-step filling

Because big fruit grain grain, one has2g~4gIt is difficult to achieve high precision with only fruit piston filling valve, so the capacity is80%Fruit piston valve, to carry out the initial filling, after the initial filling, to the weighing filling module, total weight check, on the remaining20%Two speed liquid filling valve is used for fine filling. Ensure high accuracy of fruit grain.

-

Pressure to accelerate

Our companyVLS(Virtual real-time control of liquid level) Filling system (optional), which can accelerate the filling of thick materials with pressure, and also can defoam products easy to bubble with negative pressure or pressure.

-

CIP/SIPcleaning

CIP/SIPCleaning, access to most plants equipped with the whole plant cleaning system.

-

Continuous production

Continuous production time up to72hours~96Hours.

-

External cleaning

If the customer needs, can buyCOP/SOPExternal spray piping system, can cooperate with the customer's external cleaning machine for cleaning.

Mobile QR code

Mobile QR code Official account

Official account