-

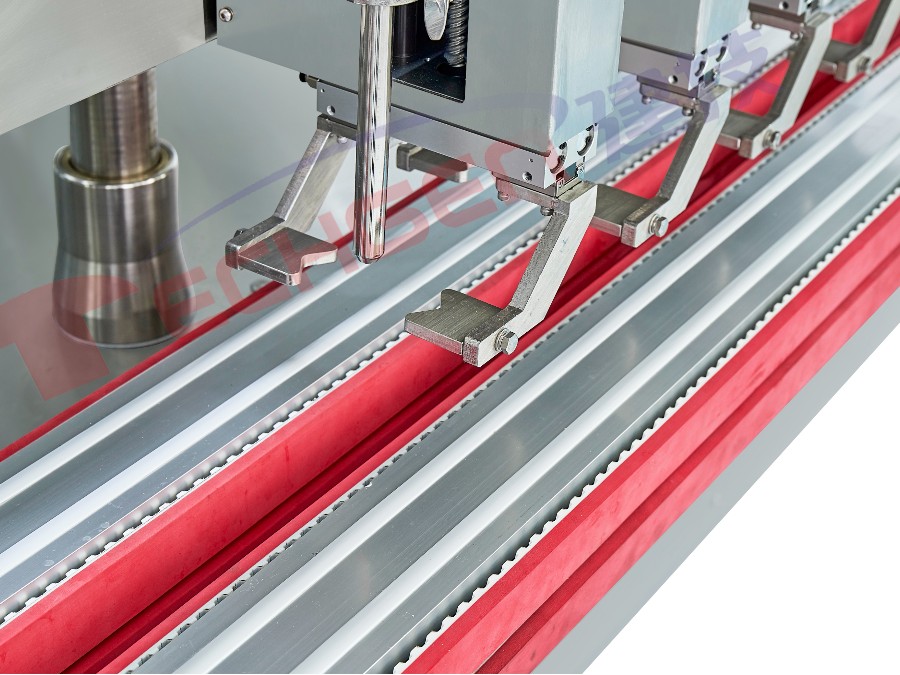

High quality material

Material contact parts are made of stainless steelSUS316orSUS304;

-

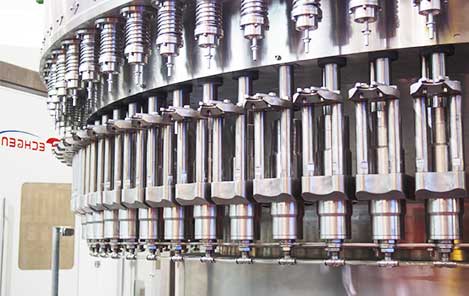

Double speed filling

Filling valve adopts double speed filling, with fast filling and slow filling function;

-

One key operation

Adopt motion controller andHMIMan-machine operation interface, parameters can be called by one key in the operation interface;

-

High filling precision

High precision electronic scale, high filling precision;

-

No bottle no filling

The bottle feeding system adopts photoelectric detection, so that there is bottle filling, no bottle filling;

-

Drip tight

Anti-drip, anti-splash design, can effectively solve the phenomenon of oil dripping.

-

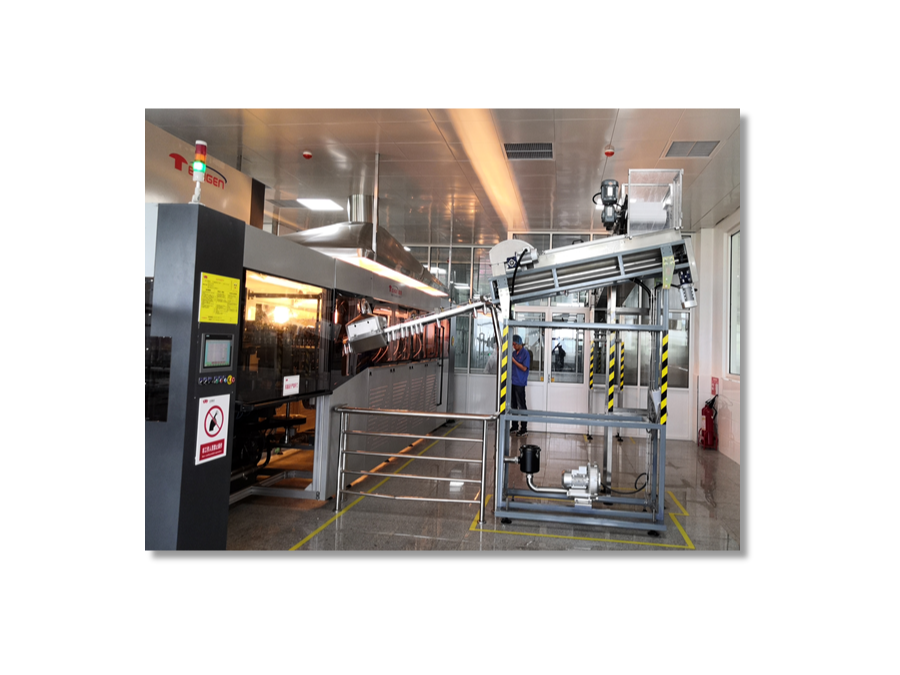

To adapt to the diverse

Filling machine has lifting adjustment device, suitable for different bottle filling.

-

Cleaning without dead Angle

Material tank with cleaning device, easy to clean without dead Angle, suitable for a variety of material production;

-

To reduce pollution

The filling gland is carried out synchronously to reduce pollution and ensure food installation.

Mobile QR code

Mobile QR code Official account

Official account